"AANAL MAGNETIC" manufacture a wide range of Rare Earth and Ferrite Magnetic Pulleys. These Pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt. The permanent magnetic pulley is dual-purpose equipment used for protection of crusher Jaws or other machinery and also for purification and concentration of magnetic material from the mines. It has the widest application in food, chemical, ceramic, paper, coal handling, foundry operation and mining industry.

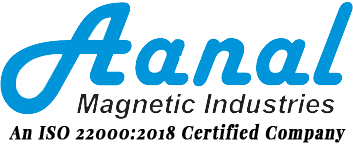

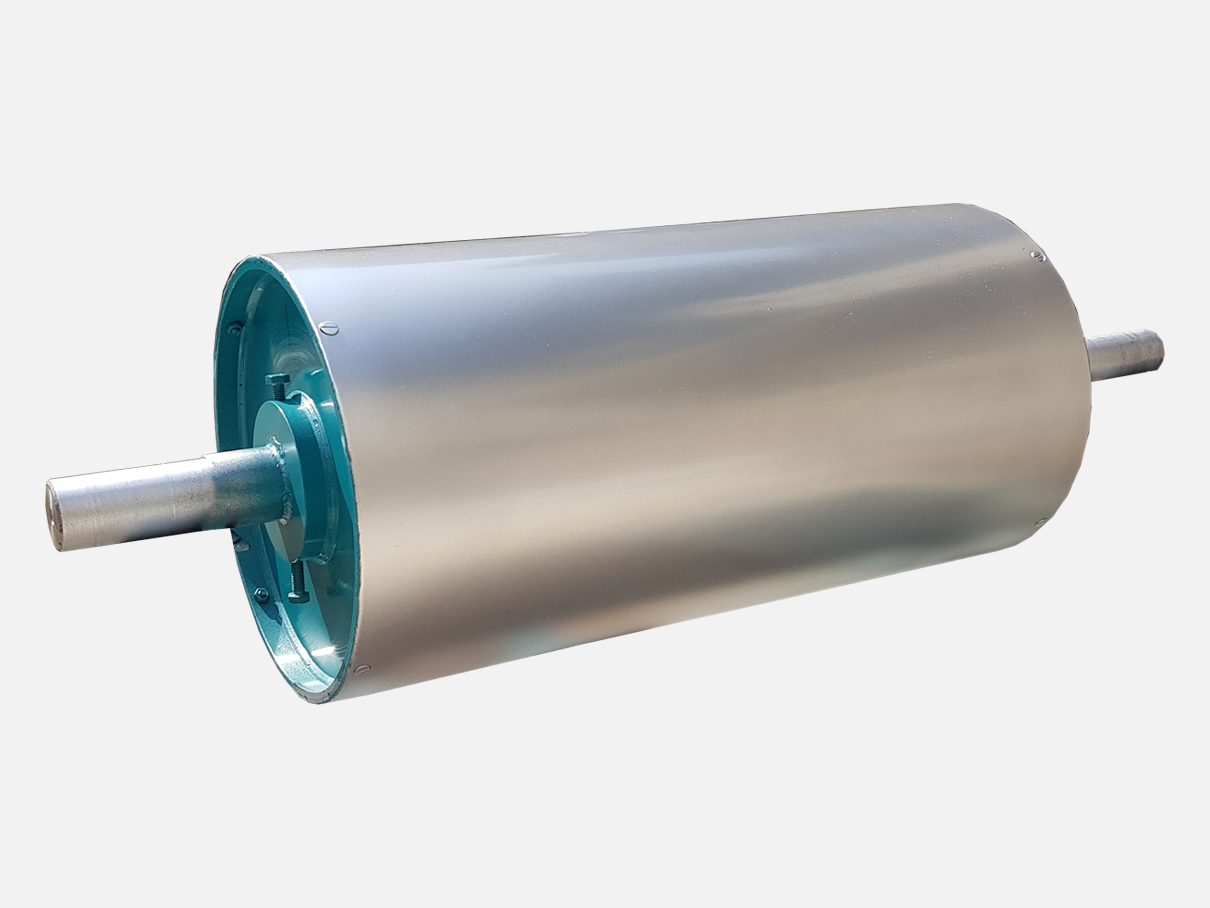

The magnetism in a Permanent Magnetic Pulley is generated by internal assembly of magnets enclosed in non magnetic Stainless Steel shell. The steel shaft is extended on both sides. One side is provided with Key-way. The Pulleys have a face width of 50 mm to 100 mm more than the belt width. The magnetic strength of the pulley depends on the diameter and also quality of magnets used. Pulleys with Rare Earth Magnets can handle depths up to 300 mm. Pulley width is determined by width of conveyor belt to be used. Diameter depends on depth of material and speed of the conveyor. It can be designed to suit custemers specificapplication.

The magnetic Drum pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the drum pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. Head roller magnets for conveyor belt are supplied in permanent magnets.

Features

- 304 stainless steel faces.

- Removable mild steel shaft.

- Four hub styles.

- Flat face.

- Key way and set screws.

Options

- Taper locks

- Crowned face

- Fixed shaft

- Lagging

- Stainless steel shaft