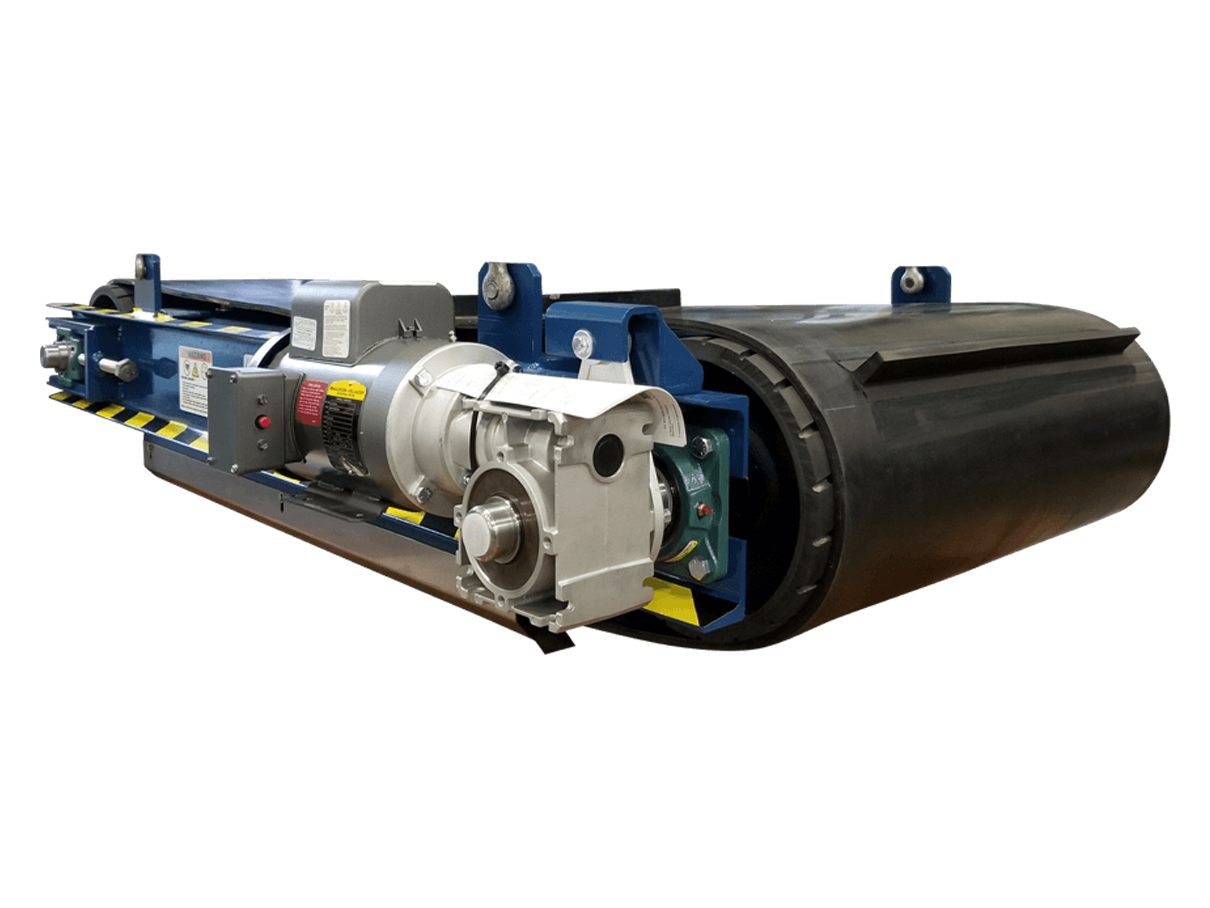

A belt magnetic separator is a type of magnetic separation equipment used to extract and separate magnetic materials from a mixture of non-magnetic materials. It is commonly used in industries such as mining, recycling, and bulk material handling to remove ferrous contaminants from conveyed materials. The key component of a belt magnetic separator is a conveyor belt that moves material across a stationary magnet assembly.

Here are the main features and components of a typical belt magnetic separator:

Conveyor Belt : The conveyor belt is the primary component of a belt magnetic separator. It carries the material to be separated over the stationary magnetic assembly. The belt is made from a durable material that can withstand the wear and tear of the process.

Stationary Magnetic Assembly : This assembly typically consists of one or more powerful permanent magnets or electromagnets that generate a strong magnetic field. The magnetic assembly is positioned beneath the conveyor belt, so as the material passes over it, the magnetic field attracts and retains ferrous or magnetic particles from the material.

Adjustable Conveyor Speed : The speed of the conveyor belt can often be adjusted to optimize the separation process and accommodate different types of materials and separation requirements.

Adjustable Magnetic Field Strength : Some belt magnetic separators allow you to adjust the strength of the magnetic field generated by the magnets to optimize the separation efficiency.

Discharge Chutes : Once the ferrous contaminants are separated from the material, they are usually directed to a separate discharge chute for collection and disposal.

Applications of belt magnetic separators include:

Mining and Ore Processing : Belt magnetic separators are used to extract and separate magnetic minerals from non-magnetic ore, improving the quality of the final product.

Recycling : In recycling facilities, they remove ferrous contaminants from materials like shredded tires, plastic, glass, and metal, ensuring product quality and safety.

Bulk Material Handling : In industries that transport bulk materials on conveyor belts, belt magnetic separators help prevent damage to downstream processing equipment and maintain product quality.

Food Processing : Belt magnetic separators are used in the food industry to remove metal contaminants from products like grains, flour, and various processed foods to meet food safety standards.

Belt magnetic separators are designed to operate continuously, making them a reliable and efficient solution for the removal of magnetic contaminants from a variety of materials in various industrial applications. Their permanent magnet or electromagnet design ensures a constant magnetic field without the need for an external power source, making them energy-efficient and cost-effective.