Suspension Type Magnets use is recommended for low contamination products. If the frequency of the impurities is very much, it will make a layer shunting magnetic field. Hence, the equipment required frequnet cleaning. Over band type Magnetic Separator is recommended for this type of application.

The principal applications are for processing of bulk products such as Culets, Glass, Cofee, Cereals, Minerals, Coal and Sugar etc.,

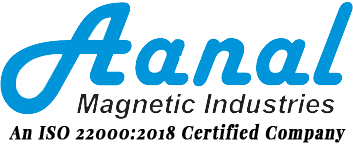

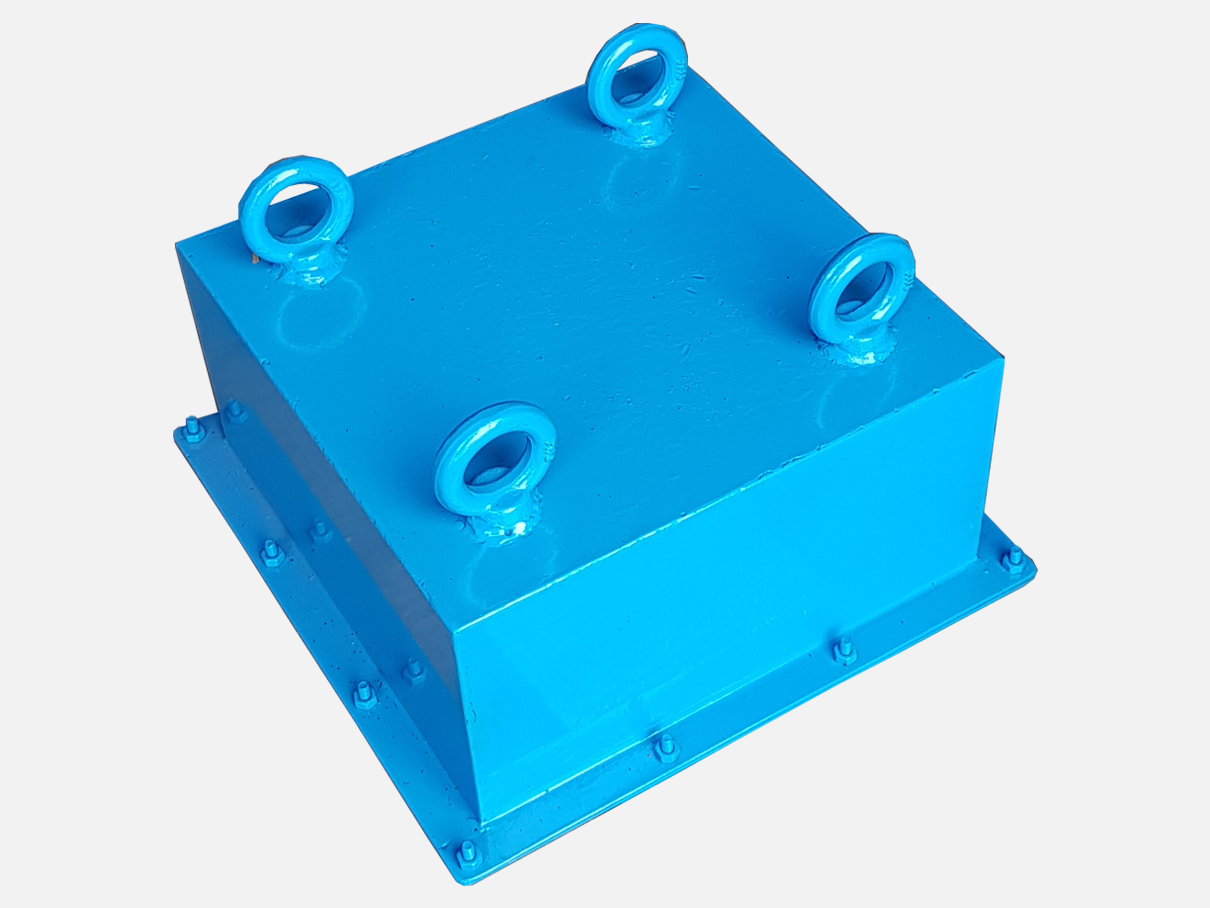

AANAL magnets can be installed at the end of belt above the head drum (Image-1) or across the Conveyor belt (Image-2)..

Toavoid disturbances to the magnetic field, in both cases, the magnetic parts must be placed below the surface of the magnet.

The installation shown in Image-1 is recommended for high speeds. Due to trajectory of the products and the fact that it is then fluidized, separation is more efficient.

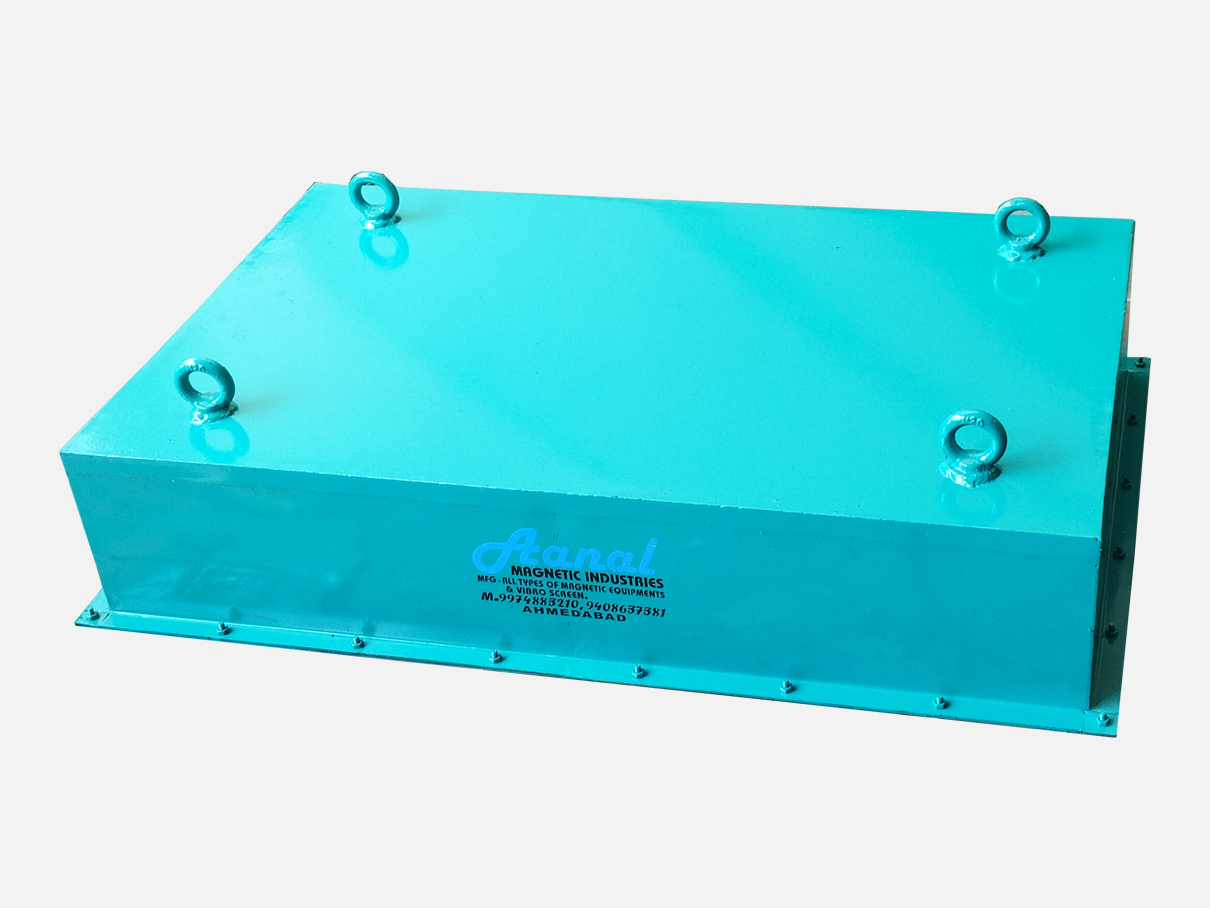

We are one of the leading suspended magnet manufacturers in Ahmedabad. With a vision for quality and excellence, we have been offering a superior range of suspended magnets for extracting iron from the product stream. Designed using optimum quality materials and quality tested components sourced from certified and reliable vendors, our suspended magnets are highly appreciated by our clients across the globe. Being a customer centric firm, we offer these suspended magnets in customized specifications as per the precise needs of our clients. You can avail them at economical prices in the market.

We have a team of skilled and experienced professionals who work devotedly and dedicatedly to offer specialized services to our clients. They always strive for 100% customer satisfaction and aim to add value to your business. Owing to high belt speed, robust construction, longer service life, higher durability and low maintenance, our suspended permanent magnets are highly acclaimed in the market. All our suspended magnets are checked for quality at various stages of production by experienced quality analysts and manufactured in adherence to the industry norms.

Being a leading suspended magnet manufacturers, we understand the importance of providing high quality Material free from Iron Particles. Hence we strive to meet the challenges faced by our clients enabling them to consistently provide Iron Free row material. Owing to reasonable prices, compact design and high performance, our high quality suspended magnets are widely used in the Mining Industries, on the Top of the Conveyor Belt To Remove The Iron Particles from your Material. Designed using advanced technology they boast of exceptional features and offer an enhanced performance taking your business to a whole new level.

Owing to highly advanced production processes and a team of skilled engineers, we have been able to fulfill the ever increasing demands of our clients. As our suspended permanent magnets meet the most demanding industry requirements, we have emerged as a trusted suspended magnets manufacturer.