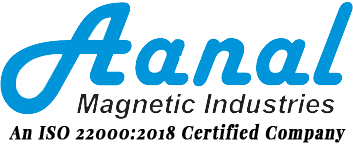

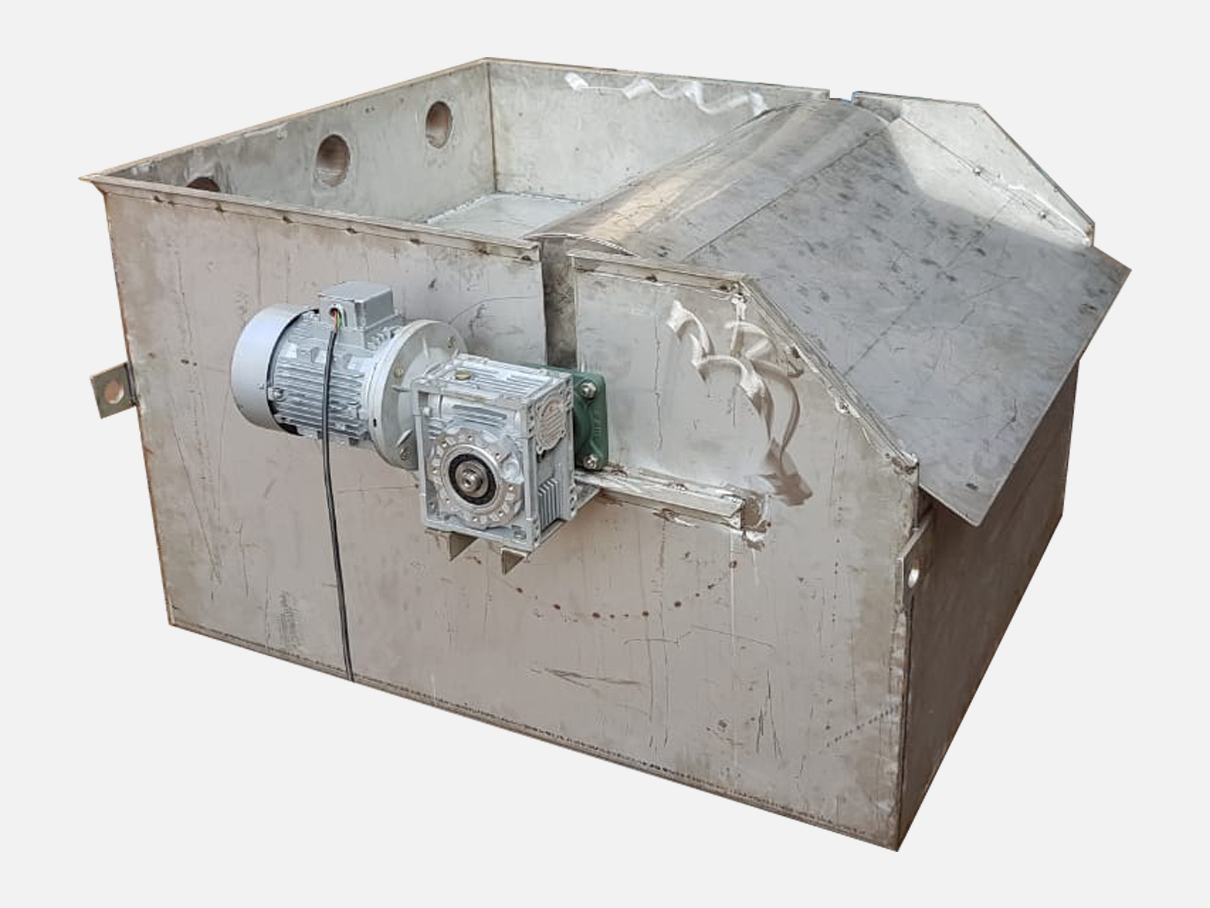

The wet magnetic drum separator (known as NTS) is used to remove very fine magnetisable components from low concentration, low-viscosity liquids. NTS is mainly used by metal processing industry and for the treatment of pre-concentrates extracted from high gradient magnetic filter. About 90% of the very fine magnetisable components can be separated as sludge. Features such as stainless steel housing and powerful neodymium iron boron magnets are standard.

General Principles

The liquid flows through a semi-circular separating chamber beneath a stainless steel drum to which the magnetisable particles are attracted. The strong, high-gradient magnetic field is created by a cylinder consisting of permanent magnetic discs positioned within the drum. These special permanent magnets generate particularly high field gradients which are necessary for successful separation, as is the need with all Magnetic-Separators.

For recovering Magnetic/Ferro-silicon in dense media plants and iron ores, wet drum separators are mainly used. They remove contamination from the product stream, increasing product purity and plant productivity. In the applications where the product purity is most essential, the wet drum separators can use powerful Rare Earth Magnets, which can remove very fine and weak contaminants even from dense materials.

Features

- Wet drum magnets have high magnetic recovery and discharge.

- The feed slurries recover the magnetic.

- It is available in single or multiple drum applications.

- Recover magnetic solids in as clean as a magnetic concentrate.

- Permanent magnet assembly eliminates coil burn-outs

- The magnet/pole elements are bolted to a mild steel shaft.

- The drum is made from thick stainless steel for long service life.

- Wet drum separators are available in different configuration like single drum, double drum and multiple drum. In double drum two separators are arranged back to back with a common feed back.

Applications

- Glass industry

- Chemical industry

- Plastic industry

- Mining industry

- Food industry

- Pharmaceuticals industry

- Foundry industry

Buyers Advantages

Buyers have the following advantages:

- The separator provides minimum wear on the cylinder.

- The materials are returned to the feed point automatically.

- It has the high magnetic solid discharge

- It can also handle heavy magnetic load.

- Wet drum separator has wide industrial usage.